PINCURE C

INNOVATIVE, HIGH POWERED UV LED PINNING

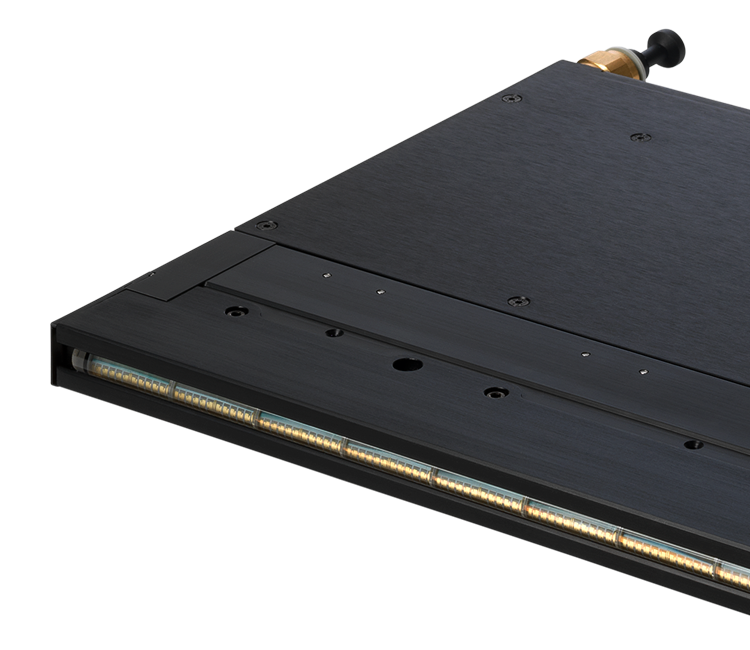

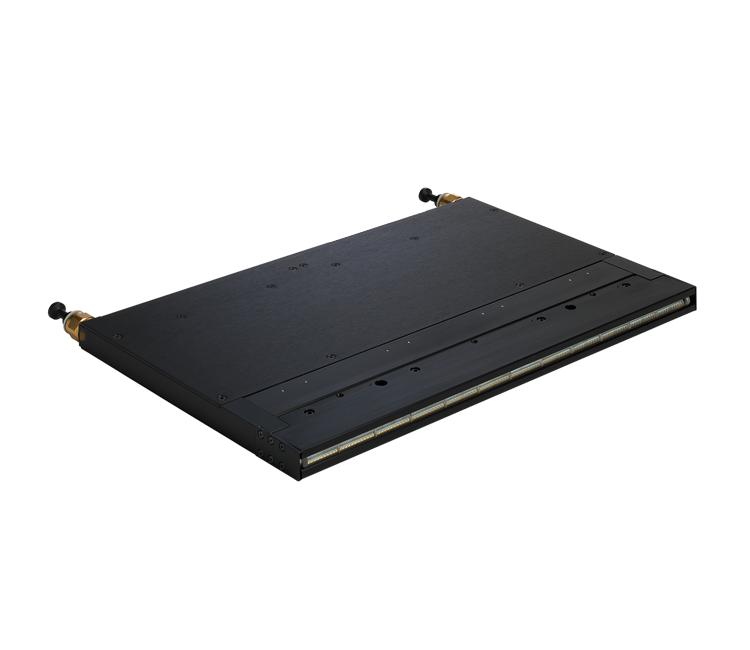

Pincure C & CX UV LED offers a powerful solution in a compact water cooled package for ultimate high speed pinning between inkjet print heads.

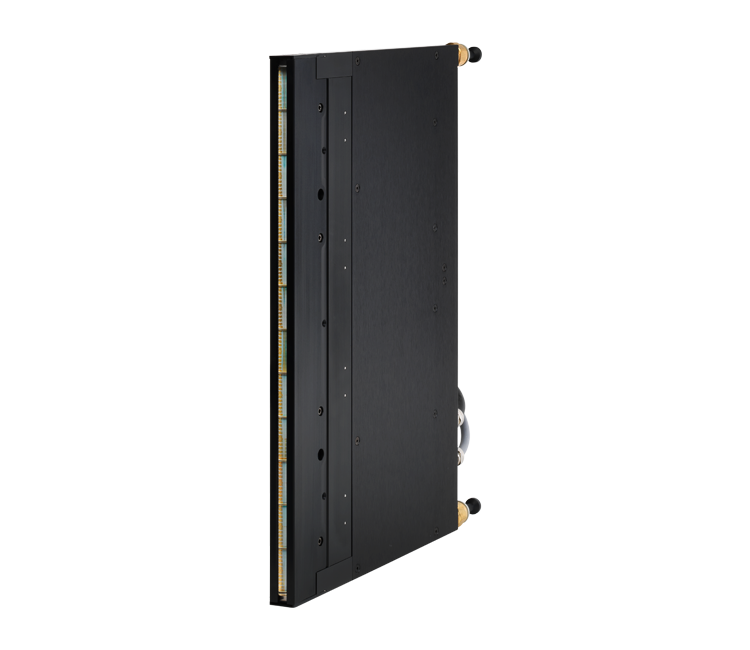

The Pincure C delivers variable output up to 3.5W/cm² while the CX model delivers variable output up to 10W/cm² for heavy pinning of dense white inks.

The proven optics of the original Pincure model (which eliminates the risk of UV light damage to the print head nozzle plates) has been further enhanced, and in Pincure C series is now housed within a clever design which prohibits media contact and contamination to the lens.

POWER

POWER

3.5W/cm²

WINDOW

WINDOW

7mm*

WAVELENGTH(S)

WAVELENGTH(S)

405nm, 395nm, 385nm, 365nm

XT8

XT8

YES

ADDRESSABLE

ADDRESSABLE

YES

FOCUSSED

FOCUSSED

YES

DIMENSIONS

DIMENSIONS

[X] x 20mm x 148mm

WEIGHT

WEIGHT

600g

FUNCTIONALITY

The high intensity of the Pincure ensures that each ink droplet is frozen on the media as it is jetted, but with a surface energy tension which readily accepts further droplets, giving an effective colour ‘lift’ without any inter-layer adhesion problems. Furthermore, each array features infinitely variable output allowing it to be ‘tuned’ to the individual colour or type of ink being jetted. The high speed switching of the Pincure array allows it to be switched on and off in sequence with the printhead, thereby eliminating the risk of stray UV light reflecting back into the printheads and causing irreparable damage.

High intensity LED arrays need precise cooling to give optimum output: the cooler the temperature of the LED’s, the better the UV output. The advanced water cooling system of the Pincure ensures that it can be placed alongside a heated printhead without any risk of thermal cross interference. Designed in-house at IST INTECH’s R&D unit in the UK, the super slim Pincure is accurate, efficient and low-cost to buy and run, with no consumable parts or service requirements.

KEY FEATURES

XT8: UV LED BOOSTER

XT8: UV LED BOOSTER

With XT8 UV LED Booster technology, the system reaches an extremely high output and dose which greatly increases cure speeds offering customers a wider choice in all applications. An extended service life is achieved since the semi-conductor chips are not being driven as hard when compared to other products on the market. The 30% boost in efficiency is available for systems fitted with 365, 385, 395 or 405nm.

WARRANTY

WARRANTY

IST INTECH grants a warranty of five years on each XT8 LED module (one shift operation). ITL UV LED curing solutions are fitted with field replaceable modules offering extended service life and are covered by a comprehensive warranty backed by global support direct from IST INTECH and through its strategic partner IST Metz.

GET IN TOUCH

LOOKING FOR A

CUSTOMISED SOLUTION?

We are here to help…

IST INTECH has the in-house capability to design, manufacture and deliver unique bespoke solutions, making us not just another off-the-shelf UV or UV LED supplier. Contact us using the form adjacent to discuss your requirements.

Call us on:

+44 (0) 1869 233611