GLOSSARY

GLOSSARY OF TERMS

New to the world of UV LED curing systems and looking for a comprehensive guide to the terminology used in the industry? Our glossary of terms page is here to help.

From technical jargon to industry-specific language, we’ve compiled a comprehensive list of definitions to help you navigate the complex world of UV LED curing with ease.

ABSORPTION

a process in which matter acquires photonic energy from electromagnetic radiation as wavelengths travel through or reflect off matter.

ADDITIVE LAMP (HALIDE LAMP)

medium pressure mercury vapour lamp (arc or microwave) containing metal additives such as iron (Fe), gallium (Ga), lead (Pb), tin (Sn), bismuth (Bi), or indium (In). Additive lamps have UV spectral emissions that are different than those of standard mercury (Hg) lamps. Sometimes referred to as doped lamps or metal halide lamps.

ADDRESSABILITY

A UV LED head is made on many hundreds/thousands of individual LED’s. In it’s simplest form, addressability is the capability to switch these LED’s on and off as required, or vary their intensity.

ADHESION

the bonding of a chemistry to an adherend (substrate) consisting of intermolecular forces, chemical bonds, and mechanical or interlocking interactions. The strength of adhesion is dependent on the adhesive, adherend (substrate) and cure.

ANODE

positive terminal of an electronic device – in this case a LIGHT EMITTING DIODE (LED).

ARC LAMP

see mercury arc lamp

ARC LENGTH

distance between electrodes in a mercury lamp (bulb). See effective cure length.

ASTM D3359

ASTM test method used to perform a cross-cut or cross hatch adhesion test. An X-cut or lattice pattern of 6 or 11 cuts are scratched through the UV cured material to the substrate. Special pressure-sensitive tape is then applied over the cuts and then pulled away. Pulling the tape away from the substrate reveals the degree of adhesion of the cured formulation to the substrate or media. If any material between the lines is removed with the tape, adhesion is poor. If the cured material remains, adhesion is good. The recommended guidelines for testing and evaluation are documented in ASTM spec D3359 under Methods A and B. Method A employs the X cut and is used in the field as well as for films greater than 5 mils. Method B calls for lattice cuts and is recommended for use in the lab and for films that are 5 mils or less in thickness. Adhesion is assessed qualitatively against a scale of 5A or 5B (best adhesion) to 0A or 0B (worst adhesion). This test method is similar in content but not technically equivalent to ISO 2409.

BALLAST

a device used to power an arc lamp or mercury arc lamp. Could be an inductor (commonly known as a Choke) which is a coil of wire wound around a metal core or an electronic version that does the same task. In both cases it is a current limiting device preventing a short circuit situation.

BANDWIDTH

range of wavelengths between two identified limits and expressed in the same units of wavelength measure (nanometres in the case of ultraviolet and visible output)

BINNING

sorting discrete UV LEDs according to characteristics of peak irradiance, wavelength, and forward voltage among others in order to ensure similarity of operation.

BLACK LIGHT

any lamp or spectral emission predominantly consisting of longer UVA and minimal near visible output. Lights typically used in nightclub/disco that fluoresce with white clothing.

BOROSILICATE

type of heat-resistant glass made from silica and boron trioxide that exhibits exceptional thermal shock resistance and transmits more ultraviolet energy than standard glass. Borosilicate is often used in UV curing systems for plates, windows, reflectors, lenses, and other optics.

BULB (LAMP)

A UV Curing Lamp is a sealed quartz tube containing a mixture of mercury and inert gas under medium pressure. Electrode UV lamps (bulbs) are fitted with electrical connections at the ends of the lamp (bulb). Microwave UV lamps (bulbs) contain no electrical connections. The internal mercury and inert gas are vaporised into a UV emitting plasma by a high voltage arc or microwave energy.

BURN-IN-PERIOD

stage of the start-up process for a UV lamp (bulb) where the current and voltage inside the lamp (bulb) proceed from inrush through to stabilisation and reach steady-state operation time period to achieve steady-state operation during start-up time period a new lamp (bulb) or new lamphead is powered in a performance test at the manufacture before shipmen

CASSETTE / CARTRIDGE /CRADLE

Cationic Chemistry is a different sort of chemistry that only requires the UV to start the reaction, the reaction then then continues to completion even when removed from the UV light source, this can take sometime.

CATHODE

negative terminal of an electronic device, but in this case a light emitting diode (LED)

CATIONIC CHEMISTRY / CATIONIC CURING

Cationic Chemistry is a different sort of chemistry that only requires the UV to start the reaction, the reaction then then continues to completion even when removed from the UV light source, this can take sometime.

CHIP

A chip is sometimes referred to as a diode, die, or semiconductor. Layers of semiconducting material doped and processed to have p-n junction characteristics. Gallium nitride (GaN) is the material commonly used to generate longer 385, 395, and 405 nm wavelength LEDs as well as blue visible LEDs. Aluminium gallium nitride (AlGaN) is the material used for 365 nm LEDs.

CHOKE

an inductive device that limits and stabilises the amount of current flowing through an arc lamp (bulb), so power output remains constant. Sometimes referred to as a ballast.

COLD MIRROR

a type of mercury lamp reflector coated with a dichroic material that passes or absorbs infrared wavelengths while reflecting UV wavelengths toward the cure surface. See dichroic.

COOLANT

water or a specific water-solvent solution that flows in a cooling system. In UV LED system it flows through a manifold to remove heat generated by electrical current passing through the diodes maintaining the desired junction temperatures during operation. May also be used to cool components in a UV Lamp system.

CROSS-CUT / CROSS HATCH

test for measuring adhesion – see ASTM D3359 and ISO 2409.

CROSSLINKING

conversion of the monomers into polymer chains

CURE / CURING / CURED

a general term to express the state of polymerisation of the chemistry

CURE LENGTH

see effective cure length.

DC POWER SUPPLY

device that supplies electric energy at constant voltage to power LEDs or other electrical components. DC means direct current. Direct current is an alternative to AC or alternating current.

DICHROIC

a coating designed to transmit or absorb certain wavelengths while reflecting other wavelengths. In UV lampheads, dichroic coatings are sometimes applied to reflectors for the purpose of transmitting or absorbing infrared energy while reflecting UV energy toward the cure surface. See Cold Mirror

DIE / DIODE

A die or diode is sometimes referred to as a chip or semiconductor. An electronic component that only allows dc current to pass through it in a single direction.

DOPED LAMP (BULB)

see additive lamp.

DOSE (DOSAGE)

Dose can be referred to as the total amount/volume of UV. Dose is frequently and incorrectly used as a synonym for energy density which, for clarification, is total delivered energy as opposed to absorbed energy. See energy density.

DOSE RATE

another term for irradiance (W/cm2 or watts per square centimetre) with equivalent units of J/s/cm2. Commonly called Intensity, or how bright the light is.

DOSE TEST STRIP

See UV energy density test strip.

DRIVER / DRIVER BOARD / DRIVER CARD

Current limiting device to maintain the current running through an LED and prevent over running.

DUAL CURE

more commonly this is a chemistry that contains a solvent (water can be a solvent) to ease application issues, this solvent must be evaporated before final (UV) curing is possible.

DUTY CYCLE

duty cycle simply refers to the On time of the system compared to the off time. So if the system is on all the time this is referred to as a 100% duty cycle. A lower duty cycle opens up opportunities in the construction of a UV LED system to reduce the amount of cooling required to maintain the correct junctions temperature. Sometimes a UV LED source can be controlled using a PWM (pulse width modulation) control, this effectively flashes the system on/off for periods of time, however care should be taken that the off time does not leave areas of the chemistry not exposed to the UV output.

EFFECTIVE CURE LENGTH

portion of lamp (bulb) length that emits optimal and relatively uniform UV output. For electrode lamps (bulbs), the effective cure length is always slightly less than the arc length. For microwave lamps (bulbs), the effective cure length is the length of the lamp (bulb). UV LED lamps emit a bit less output towards the ends of the array.

ELECTRODE

electrical fitting at each end of an arc lamp (bulb). The electrode consists of a tungsten pin surrounded by a tungsten coil and is used to maintain a voltage arc across the lamp (bulb). Electrode also refers to the style of lamp (bulb) or system when differentiating between microwave and electrode arc lamps and microwave and electrode systems. Electrode lamps and systems are also referred to as arc lamps and arc lamp systems.

ELECTROLUMINESCENCE

phenomenon where electromagnetic radiation of specific wavelengths is emitted when electric current flows through materials with inherent optical properties.

ELECTROMAGNETIC SPECTRUM

continuous range of all radiation in the universe; segmented into gamma rays, x-rays, ultraviolet, visible, infrared, and radio waves; and discretely quantified by wavelength, frequency, and photonic energy. See: DOSE AND INTENSITY WHITEPAPER

EMITTING WINDOW

flat rectangular piece of UV transparent quartz or borosilicate secured and often sealed at the base of an LED lamphead or mercury arc lamphead to physically protect internal components and limit foreign matter ingress. See quartz plate.

ENCAPSULATE

transparent material sometimes used around individual or small groups of LEDs to provide added protection and seal from dirt and moisture.

ENERGY DENSITY

total radiant energy arriving at a surface per unit area and expressed in J/cm2 or mJ/cm2. Energy density is the integration of irradiance (W/cm2 or mW/cm2) over exposure time (line speed or dwell). Though technically incorrect, energy density is commonly referred to as dose.

ENERGY DENSITY TEST STRIP

see UV energy density test strip

EXCIMER LAMP

specific type of quasimonochromatic emitting source that spontaneously generates UV emitting excimer or exciplex molecules. A typical method of emission generation is via dielectric barrier discharge (DBD). Commonly utilised excimer wavelengths are 172, 222, and 308 nm.

FLOOD

an unfocused emission of UV energy that is evenly distributed across the width and length of a reflector.

FLOOD CURING

Flood curing or Area curing as it is sometimes referred to, is generally used for the curing of static two dimensional substrates.

FOCAL DISTANCE (LENGTH)

perpendicular distance from the edge of a focused lamphead to the location where the UV energy emitted from the lamp (bulb) is concentrated. This is the location of maximum UV concentration.

FOCUS

narrow band that runs parallel to the lamphead where reflected UV energy is at its highest concentration.

FORWARD VOLTAGE

voltage drop across a semiconductor when the anode of an LED is connected to the positive terminal of a DC voltage supply and the cathode of the LED is connected to the negative terminal.

FREE RADICAL CHEMISTRY / FREE RADICAL CURING

An acrylate reaction where the free radicals within the chemistry are activated by exposure to UV light and cauase the monomers to combine and form polmers, this reaction stops when the UV light source us removed.

GALLIUM (GA)

Gallium additives produce a violet coloured UV output when vaporised. Gallium bulbs have a spectral peak around 417 nm and a spectral concentration between 400 and 450 nm. They are often used when deeper cure is required or with white formulations containing titanium dioxides. In some industries, microwave gallium bulbs are referred to as V bulbs.

GELLING

In the context of printing and coating, “gelling” typically refers to a phase in the ink or coating process where the liquid ink/coating begins to solidify or gel before it is fully cured. This phenomenon is particularly relevant in processes that need time to partially set or gel before additional printing or finishing steps take place. For instance, “gelling” or “pinning” of opaque white ink is needed in order to have optimum surface for receiving further colours for a good printing quality. Or for instance, “gelling” of top coating is needed in order to be able to mattify using an Excimer for a smooth surface.

GERMICIDAL

any lamp or spectral emission predominantly consisting of UVC output. See UV Sterilisation

HUMAN MACHINE INTERFACE (HMI)

touch screen controls and dashboards that enable user friendly operation of manufacturing equipment.

IGNITER

see starter

INDIUM (IN)

a silvery white metallic element used in additive mercury lamps (bulbs). Indium additives produce a violet coloured UV output when vaporised. Indium is used to shift the spectral output past 400 nm. In some industries, microwave indium bulbs are referred to as Q bulbs.

INFRARED

portion of the electromagnetic spectrum between 700 nm and 1 mm. Dominant contributor to radiated heat emitted by electrode and microwave UV curing systems. Infrared is not emitted by UV LEDs.

INTEGRAL SHUTTER

a pneumatically or electrically actuated assembly integrated into mercury arc lampheads and used to block UV output when closed. Some shutters have a dual purpose with the internal surface serving as the reflector when open.

INTENSITY

a common term used to describe the brightness of the light. Technically incorrect, but the term is easily distingushible from other terms. See DOSE & INTENSITY whitepaper

INTERLOCK

internal or external device to a UV curing system that enables or disables another system function. An internal interlock can be a temperature, pressure, or flow meter sensor designed into the cooling system to monitor proper conditions and adjust or switch off UV system components when conditions are not met. An external interlock is typically implemented by the integrator or machine builder. It is a safety feature that prevents the emitting source from turning on or forces a shut off under certain conditions such as when a machine door is open or when the web or parts stop moving.

IRRADIANCE

radiant power arriving at a surface from all forward angles per unit area. It is expressed in watts or milliwatts per square centimetre (W/cm2 or mW/cm2).1 Irradiance is independent of line speed and exposure time. It decreases at the cure surface as the distance between the cure surface and the emitting source increases. Though technically incorrect, irradiance is commonly referred to as intensity. Other commonly used terms for irradiance include dose rate, power density, and watt density.

IRRADIANCE PROFILE

irradiance pattern of a lamp, or, in the case of dynamic exposure, the varying irradiance at a point on a surface that passes through the field of illumination of a lamp or lamps; irradiance vs. time.

ISO 2409 STANDARD

ISO test method used to perform a cross-cut or cross hatch adhesion test. A lattice pattern of 6 cuts are scratched through the UV cured material to the substrate. Special pressure-sensitive tape is then applied over the cuts and then pulled away. Pulling the tape away from the substrate reveals the degree of adhesion of the cured formulation to the substrate or media. If any material between the lines is removed with the tape, adhesion is poor. If the cured material remains, adhesion is good. Adhesion is assessed qualitatively against a scale of 0 (best adhesion) to 5 (worst adhesion). The recommended guidelines for testing and evaluation are intended for the laboratory but are suitable for field testing. Not suitable for coatings of thickness greater than 250 µm or for textured coatings. Similar in content but not technically equivalent to ASTM D3359.

JOULE

metric unit for measuring work or energy. One joule is equivalent to the work done by a force of one Netwon (N) acting through one meter (m) and alternatively expressed as newton-meter. A joule is the time-integral of power where one joule equals one watt-second and is abbreviated J or mJ for millijoule.

LAMBERT’S COSINE LAW

In OPTICS, Lambert’s cosine law says that the RADIANT INTENSITY or LUMINOUS INTENSITY observed from an ideal DIFFUSELY REFLECTING surface or ideal diffuse radiator is DIRECTLY PROPORTIONAL to the COSINE of the angle θ between the direction of the incident light and the SURFACE NORMAL; I = I0COS(Θ).[1][2] The law is also known as the cosine emission law[3] or Lambert’s emission law.

LAMBERTIAN

when an emitting surface has the same radiance when viewed from any angle. In other words, it has the same apparent brightness or luminance

LAMP (BULB)

sealed quartz tube containing a mixture of mercury and inert gas under medium pressure. Electrode UV lamps (bulbs) are fitted with electrical connections at the ends of the lamp (bulb). Microwave UV lamps (bulbs) contain no electrical connections and are electrodeless. The internal mercury and inert gas are vaporised into a UV emitting plasma by a high voltage arc or microwave energy. Lamp is the more commonly used term in Europe and Asia while North Americans and South Americans tend to use both lamp and bulb interchangeably.

LAMPHEAD

assembly consisting of an outer housing or casing, a UV lamp (bulb), an integral or remote cooling fan, and/or liquid cooling pipe connections. An electrode arc system often contains a removeable cassette subassembly while a microwave system contains magnetrons and an RF screen. (2) refers to UV LED curing assemblies despite UV LED emitting sources not using traditional quartz lamps (bulbs).

LED (LIGHT EMITTING DIODE)

layers of semiconducting material doped and processed to have p-n junction characteristics. Gallium nitride (GaN) is the material commonly used to generate longer 385, 395, and 405 nm wavelength LEDs as well as blue visible LEDs. Aluminium gallium nitride (AlGaN) is the material used for 365 nm LEDs. When a forward bias is applied to LEDs, current flows from the p-side to the n-side (anode to cathode) emitting light in the process.

LED ARRAY

sub-assembly, module, or package with one diode existing as a single point source or multiple diodes arranged in a row, in a matrix of rows and columns, or in another configuration and including the necessary wire bonds, electronics, and thermal transfer components. Occasionally micro reflectors, micro or macro optics, a protective lens, or encapsulation is integrated into an array or module. Additional system components are generally necessary to integrate, power, control, and cool the array. Curing assembly that includes one or numerous LED arrays or modules mounted in a casing or housing and equipped with a suitable air or liquid cooling system, internal heat sink, quartz window, and power and controls connection. This latter definition of an LED array is akin to lampheads and irradiators used in traditional UV curing systems.

LED LAMPHEAD / HEAD / LAMP / IRRADIATOR / LIGHT SOURCE / DRYER / LIGHT ENGINE

curing assembly that includes one or numerous LED arrays or modules mounted in a casing or housing and equipped with a suitable air or liquid cooling system, internal heat sink, quartz window, and power and controls connection.

LED MODULE / PACKAGE

array sub-assembly with one diode existing as a single point source or multiple diodes arranged in a row, in a matrix of rows and columns, or in another configuration and including the necessary wire bonds, electronics, and thermal transfer components. Occasionally micro reflectors, micro or macro optics, a protective lens, or encapsulation is integrated into a module or package. Additional system components are generally necessary to integrate, power, control, and cool the module or package.

LENS

transparent micro or macro optical device often made of quartz or borosilicate and used to redirect or collimate UV output, increase irradiance over distance, and/or reduce stray light.

LIQUID CHILLER (COOLER)

refrigerated or air blast cooling system used with some arc lamp systems and some UV LED curing systems to circulate liquid coolant through lamp housings and quartz filters if used to remove heat. See coolant.

MERCURY

a hazardous silver-white metallic element that is liquid at room temperature and emits bright white UV output when vaporised into a high temperature plasma. Mercury lamps (bulbs) have a peak spectral output around 365 nm and a concentration around 254 nm. In some industries, mercury lamps (bulbs) are referred to as H bulbs. See: Mercury (Element)

MERCURY ARC LAMP

a type of gas discharge lamp where an electric arc is struck between two electrodes contained within a quartz tube to vaporise mercury and emit UV spectral output.

MERCURY VAPOUR LAMP

a type of gas discharge lamp where mercury is vaporised to emit spectral output by 1) striking an electric arc between two electrodes contained within a mercury quartz tube or 2) energising an electrodeless mercury quartz tube with microwave energy.

METAL HALIDE

see additive lamp (bulb).

MICROWAVE

portion of the electromagnetic spectrum within the shorter radar end of radio waves and having wavelengths between one millimetre and one meter. (2) an electrodeless UV curing system where the mercury inside the quartz tube is energised with microwaves.

MONOCHROMATIC

UV output consisting of a single wavelength or a narrow bandwidth. Excimer lamps are relatively monochromatic. UV LED sources are relatively monochromatic. Mercury lamps are broad-spectrum and not monochromatic. See polychromatic.

MONOMER

a type of resin molecule of relatively low molecular weight and simple structure capable of bonding with itself or other similar molecules to form UV crosslinked polymers. Monomers are reactive diluents used to adjust overall viscosity but also influence cured material properties.

NANOMETRE

metric unit of length equal to one billionth of a meter and abbreviated nm. Visible light is generally considered to be within 400 to 700 nm and ultraviolet is within the range of 100 to 450 nm.

NITROGEN INERTING / BLANKETING

when the surface of an applied formulation is flooded with inert nitrogen gas to prevent the surface chemistry from interacting with oxygen and oxidising before cure. Nitrogen inertion reduces oxygen inhibition in the chemistry.

OLIGOMER

a type of resin molecule of relatively low molecular weight and simple structure capable of bonding with itself or other similar molecules to form UV crosslinked polymers. Oligomers build the backbone of the crosslinked material and influence many of the cured material’s properties.

OPTICAL DEVICE

a micro or macro lens or other component used to direct or collimate output emitted from an LED or array of LEDs, increase irradiance over distance, and/or reduce stray light.

OXIDISING

when formulations and particularly free radicals react with atmospheric oxygen or with oxygen dispersed within the chemical mixture. Exposure to oxygen slows photopolymerisation. The greater the ratio of exposed surface area to formulation mass, the more negative the impact oxygen has on cure.

OXYGEN INHIBITION

when oxygen within the atmosphere or dispersed with the formulation reduces the number and/or strength of free radicals and slows or impedes UV cure, particularly at the surface exposed to atmosphere.

OZONE (O3)

unstable, colourless gas with a penetrating odour generated by the reaction of oxygen and UV wavelengths shorter than 240 nm.

OZONE INHIBITING / OZONE FREE BULBS

lamps (bulbs) where the quartz is manufactured with an additive or coating that prevents the transmission of shorter ozone generating UV wavelengths.

PARTS PER MILLION (PPM)

commonly used unit of concentration comparing portions of two separate quantities. One part per million is one part of a smaller portion for every million parts of a larger portion. Parts per billion (PPB) and parts per trillion (PPT) are also used. The value is unitless and is not part of the International System of Units (SI) system.

PEAK IRRADIANCE / PEAK POWER DENSITY

maximum irradiance or dose rate measured over a sample period or the maximum point on an irradiance profile. The units of measure of are W/cm2 or mW/cm2.

PHOTOINITIATOR

a molecule that absorbs UV energy and drives a polymeric chemical reaction when exposed to wavelengths within a defined range of reactivity and above a minimum threshold irradiance.

PHOTOPOLYMERISATION

chemical process where a UV formulated ink, coating, or adhesive is converted to a crosslinked polymer as a result of suitable exposure to a source of ultraviolet energy.

PINNING

process used in UV digital inkjet printing where ink is partially cured after jetting to reduce dot gain and generate a sharper more vibrant image or to cure the under white before additional colours are jetted on top of the white. A secondary, full cure UV source is required following pinning. See: Pincure C and Pincure Z

POLYCHROMATIC OR POLYCHROMIC

UV output consisting of many wavelengths. See monochromatic.

POLYMER

a substance such as plastic consisting of large molecules or macromolecules that repeat in sequence.

POSITIVE-NEGATIVE JUNCTION (P-N JUNCTION)

a semiconductor diode having a distinctly positive and distinctly negative side. The positive side is referred to as the anode or p-type region, and the negative side is referred to as the cathode or n-type region. Current flows from the p-side of the diode to the n-side when connected to a DC power source. Collectively, the device is referred to as a positive-negative junction or a p-n junction.

POST CURE

any non-specific chemical or physical reaction occurring within photopolymers after UV exposure and crosslinking has ceased. (2) refers to the process of exposing LED cured chemistry, such as in 3D printing and additive manufacturing, to a secondary UV source containing UVC wavelengths.

POWER

UV curing systems constructed with quartz tubes (lamps) are nominally rated by the electrical input power divided by the effective length of the lamp. The value is reported in watts per centimetre (wpc) or watts per inch (wpi). Power does not capture the electrical efficiency of the curing system, the spectral conversion efficiency of the lamp, the curing performance, the irradiance, or the energy density.

POWER DENSITY

sometimes used to mean irradiance. See irradiance.

POWER SUPPLY / POWER SUPPLY UNIT (PSU)

can refer to an off-the-shelf DC power supply component or an entire electrical cabinet containing the DC power supply component(s), I/O interface, AC power connection, transformers, solid state ballasts, electronics, and other items. Sometimes referred to as the Controller if it contains the operator interface or HMI

PULSE WIDTH MODULATION (PWM)

modulating or varying the width and, therefore, the frequency of a pulse. This is a digital signal that employs a duty cycle to vary the ON time that power is delivered to an electronic component. Varying the duty cycle but not the input power changes the energy density while maintaining a constant irradiance. Not all LED systems incorporate a PWM duty cycle. Many are constant current or constant wattage. See duty cycle.

QUARTZ PLATE / QUARTZ WINDOW

flat rectangular piece of UV transparent quartz or borosilicate secured and often sealed at the base of an LED lamphead or mercury arc lamphead to physically protect internal components and limit foreign matter ingress. See emitting window.

QUARTZ TUBE

a sealed tube made from silica that is filled with a precise mixture of mercury and various inert gases and sometimes fitted with electrical connections. Vaporised mercury within the quartz tube emits ultraviolet, visible, and infrared wavelengths when energised by a voltage arc or microwaves. Quartz tube is often used to refer to the lamp (bulb). (2) tube made from a silica material that is placed in front of a UV lamphead or inside the lamphead assembly and flooded internally with circulating nitrogen. Parts traveling through the tube, such as fibre optics, are safeguarded from exposure to air and ozone which facilitates cure.

RADIOMETER

an INSTRUMENT for measuring irradiance and/or energy density. See

TAKING THE RIGHT MEASURES Whitepaper

REFLECTOR

reflects and concentrates UV energy onto a cure surface. Rolled from highly polished aluminium sheet metal or formed from borosilicate into elliptical or parabolic profiles. Elliptical profiles optimise the concentration of UV energy that is reflected off a lamp (bulb) by guiding the radiation into a tightly focused UV band of energy. A parabolic reflector produces a flood of UV light at a lower peak irradiance. Holes or slots in reflectors allow cooling air to pass and are engineered for size and location to provide both optimal and balanced airflow across the length of the bulb, reflector, quartz window, and lamphead.

RF DETECTOR

monitors RF levels in the vicinity of a microwave UV curing system and signals the power supply to switch off the UV if RF levels exceed allowable limits.

SEMICONDUCTOR

a material that can be a conductor or insulator of electricity. In the case of LEDs, semiconductor conductivity and the narrow band wavelength emission depend on material construction, impurities (dopants), and concentration of dopants.

SHUTTER

an assembly designed to block UV energy emitted from a lamphead while simultaneously allowing the flow of cooling air. Shutters allow electrode arc lamps to remain powered whenever production lines stop for short periods.

SOLARISATION

effect of prolonged UV and heat exposure to a quartz lamp (bulb) that causes the quartz to devitrify or revert to a crystalline, cloudy, and opaque state that does not transmit UV energy well.

SOLID-STATE ELECTRONICS

circuits or devices built entirely from solid materials with no moving parts.

SPECTRAL OUTPUT

the radiant output of a lamp verses wavelength. It is displayed in a variety of ways, but commonly a graph or chart of output watts plotted against wavelength. The appearance of the plot will vary dramatically, depending on the wavelength resolution used. A technique of normalising is to integrate the spectral power over 10-nanometer bands (W/10nm), to reduce the difficulty of quantifying the effects of line emission spectra.

STARTER

used in electrode, ballast-based systems to vaporise the lamp mercury at start-up. Applies a several thousand-volt potential across a lamp (bulb) during start-up. An internal circuit disconnects the applied potential when current is established.

STEADYcool

STEADYcool is specifically for water-cooled UV LED systems. Specially designed water passages fitted with dynamic flow devices which greatly enhance the water cooling surface area ensuring maximum thermal transfer and cooling efficiency. See: STEADYcool

STRIKING

initiating the start-up process in which (1) a high voltage arc is applied between the electrodes in a UV lamp (bulb) to vaporise the mercury or (2) a starter bulb is used to ignite the mercury in a microwave lamp.

SURFACE CURE

refers to cure or degree of cure that occurs on the outermost material surface directly exposed to ultraviolet energy.

TAPE TEST

test for measuring adhesion – see ASTM D3359 and ISO 2409.

THROUGH CURE

refers to cure or degree of cure that occurs within formulations down to and including the material / substrate interface layer. Good through cure does not necessarily mean good adhesion.

TOTAL ENERGY

see energy density.

ULTRAVIOLET (UV)

electromagnetic radiation shorter than visible light, longer than X-rays, and spanning roughly 100 to 400-450 nm. The boundary between UV and visible is not precisely defined and is generally regarded as lying somewhere between 400 nm and 450 nm. UV wavelengths are just beyond what the human eye sees as the colour violet. See: Ultraviolet

UV ENERGY DENSITY TEST STRIP

a photsensitive strip that reacts by changing colour when exposed to UV light. The colour achieved indicates the dose of UV it has receievd.

UVA (UV-A)

portion of the electromagnetic spectrum between 315 nm and 400 nm. UVA represents the largest portion of UV energy and is commonly referred to as long UV. UVA is at the lower limit of what the human eye sees as colour.

UVB (UV-B)

portion of the electromagnetic spectrum between 280 and 315 nm. UVB is invisible to the human eye.

UVC (UV-C)

portion of the electromagnetic spectrum between 200 and 280 nm. UVC is commonly referred to as short UV or germicidal UV and is invisible to the human eye.

UVV (UV-V)

portion of the electromagnetic spectrum between 400 and 450 nm. The V stands for visible since these wavelengths are visible to the human eye and overlap a small portion of the visible spectrum.

VACUUM UV

portion of the electromagnetic spectrum between 100 nm and 200 nm. Vacuum UV does not transmit in air. Lamps that emit vacuum UV are only effective when operated in a nitrogen inerted environment.

VARIcool

The VARIcool controls the cooling according to ambient temperatures delivering a consistent output in all working environments while minimising the noise and turbulence normally associated with fan cooling. See: VARIcool

VISCOSITY (DYNAMIC)

How easy running a fluid is. Difference between water (1 centipoise) and honey (2000 centipoise)

WATT

unit of power and equivalent to one joule per second. Abbreviated as W or mW for milliwatt.

WATT DENSITY

sometimes used to mean irradiance. See irradiance.

WAVELENGTH

distance between corresponding points on a wave. Wavelengths in the ultraviolet and visible spectrum are expressed in nanometres (nm).

WIRE BOND

electrical connection or solder joint at the anode or cathode of an LED.

XT8

This innovative XT8 LED booster technology is developed by Integration Technology and helps the system reach an extremely high output and dose. The 30% boost in efficiency is available on any of our lamp heads fitted with 365, 385, 395 or 405nm or mixed wavelength arrays. See: XT8 Technology

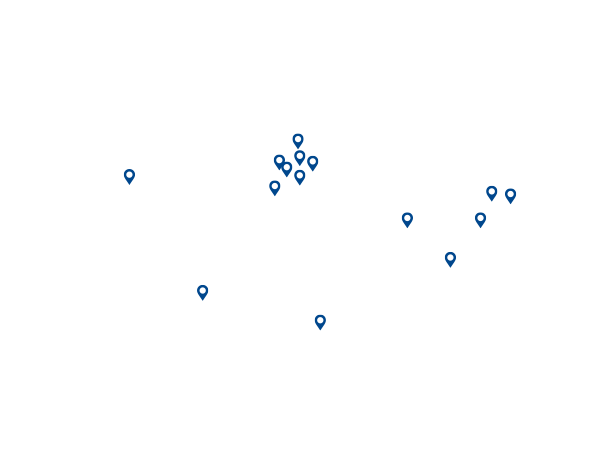

GLOBAL SUPPORT

NETWORK

Worldwide network of UV and UV LED curing solutions.

From the IST INTECH Head Offices in Oxford, United Kingdom, and from the USA, Brasil, Korea, China, and Japan, we provide ongoing regional support to Machine builders, OEMs and Integrators, ink suppliers, printhead manufacturers, and advanced manufacturing technology developers…

GET IN TOUCH

LOOKING FOR A

CUSTOMISED SOLUTION?

We are here to help…

IST INTECH has the in-house capability to design, manufacture and deliver unique bespoke solutions, making us not just another off-the-shelf UV or UV LED supplier. Contact us using the form adjacent to discuss your requirements.

Call us on:

+44 (0) 1869 233611